Semi-annual Inspection and Maintenance

At Rudesill Fire Extinguishers and Safety LLC our staff can keep track of your kitchen fire suppression systems. We can maintain its UL 300 listing and help you stay code complaint. Your kitchen fire suppression system must be inspected and maintenance on a semi-annual basis by a licensed company. The inspection and maintenance will include testing and verifying the function of the system in accordance with the owner’s manual and NFPA 17A. Our trained technician will inspect and verify your kitchen fire suppression system for the following:

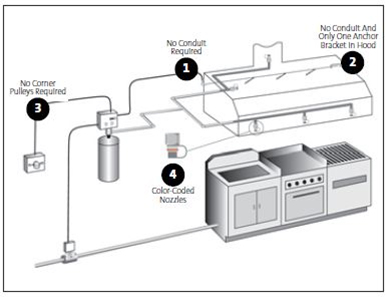

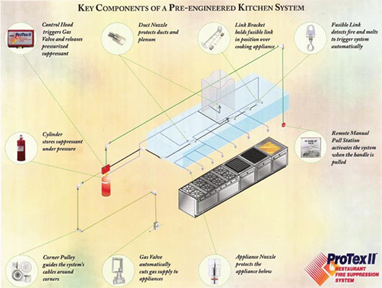

- Visually inspect distribution piping and location of appliance

- Inspect link line and position of detectors

- Inspect the automatic actuation of the fire system by cutting a terminal test link

- Test the remote pull station

- Verify electric and gas shuts off when the system is activated

- Replace fusible links

- Verify the gauge on pressurized tanks are properly charged

- Internal inspection of non-pressurized tanks

- Examine cylinders to record and verify the hydro test date

- Examine the regulator to record and verify the test dates

- Replace system cartridges when required by manufacturer

- Remove and clean nozzles to ensure they are not clogged and replace nozzle caps

- Verify nozzle are properly aligned with appliances

- Test all electrical interlocks

- Record any obvious deficiencies discovered during the inspection

NFPA 17A – 7.2 Owner’s Inspection On a monthly bases the owner shall conduct and inspection in accordance to the manufacturer listed installation and maintenance manual or Owner’s manual.

At a minimum this quick check list or inspection shall include verification of the following:

- The extinguishing system is in its proper location

- The manual actuators are unobstructed

- The tamper indicators and seals are intact.

- The maintenance tags or certification is in place

- No obvious physical damage or condition exists that might prevent operation

- The pressure gauge, if provided, shall be inspected physically or electronically to ensure it is in the operable range

- The nozzle blow off caps, where provided, are intact and undamaged

- Neither the protected equipment nor the hazard has not been replaced, modified, or relocated

If any deficiencies are found, appropriate corrective action shall be taken immediately.